Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

Floor Assemblies, Subfloors, and the Purpose of Underlayments

The components of a floor-ceiling assembly can help increase the lifespan and structural integrity of a floor going beyond what is visible in a home or office building. Underneath the wood, tile, or other floor covering, there is the subfloor, which is a structural material that is attached directly to the primary structural element, either wood or steel trusses or joists.

While some opt to install the floor covering directly over or attached to the subfloor, there are many benefits to using an underlayment layer, which adds an additional component(s) to the floor system. Underlayments provide additional benefits, including enhanced performance, appearance, and longevity.

Benefits of Underlayments

USG recommends the inclusion of an underlayment layer in a floor-ceiling assembly. It can act as a barrier to isolate impact sound, such as footsteps while also providing a smooth, clean bonding surface for finish flooring. An underlayment can also act as a bridge for structural joints, reducing strain on the finish materials caused by cyclical thermal- and moisture-related stresses. There are a variety of underlayments to meet application requirements such as water-durable substrates for bathrooms and sound-absorbing materials for thin or hard finish flooring.

Types of Underlayment

Underlayments consist of cement boards, gypsum-fiber panels, cement-fiber panels, glass-mat gypsum panels, sound mats, crack isolation membranes, poured gypsum, foam, cork, and wood-based sheet underlayments. Selecting the appropriate underlayment based on the finish flooring and use in the building, such as wet or dry areas, is an important design consideration.

The USG Solution

USG Fiberock® Underlayment and Tile Backerboard are all-purpose substrates engineered to meet floor underlayment and wall tile-backing needs throughout a home. Under resilient flooring, Fiberock® Underlayment provides a hard surface that’s stable, smooth, flat, and indentation-resistant. Behind and under tile or natural stone, Fiberock® Tile Backerboard provides an excellent bonding surface for common tile adhesives, it is stiff to resist cracking of brittle materials, such as ceramic tile, and is water resistant, a consideration in bathrooms, kitchens, entryways, and other wet areas.

Fiberock® Tile Backerboard and Underlayment panels are manufactured from an environmentally sustainable, specially engineered combination of synthetic gypsum and cellulose fibers with integral water-resistant composition that offers durability, superior performance, and exceptional tile bond. Fiberock® Tile Backerboard and Underlayment panels are engineered to meet water-, mold-, and indentation-resistance needs under and/or behind tile, resilient flooring, carpeting, hardwood flooring, and laminate flooring in new construction and/or remodeling.

The System Approach

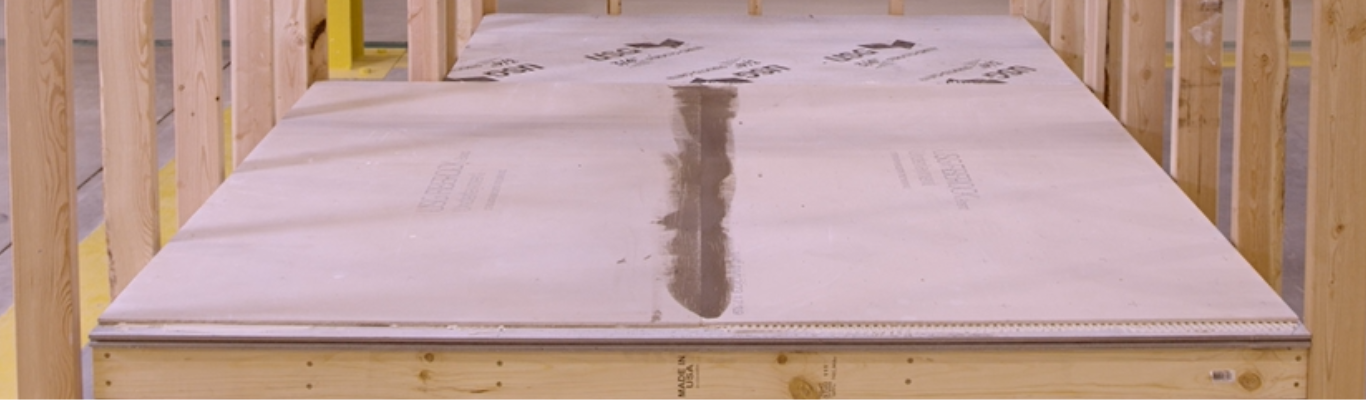

Fiberock® Tile Backerboard and Underlayment panels can be used to create acoustic- and fire-rated floor-ceiling assemblies when installed over a subfloor of USG STRUCTO-CRETE® Brand Structural Panels—more information can be found in our USG STRUCTO-CRETE® Brand Structural Panels Fire and Acoustic Manual.

STRUCTO-CRETE® Panels are noncombustible, inorganic, and mold-, moisture-, and termite-resistant structural panels used as a subfloor. Cured in-factory and dimensionally stable for use in floor-ceiling assemblies, STRUCTO-CRETE® Panels are noncombustible in accordance with ASTM E136 for use in all types of noncombustible construction. Numerous 1-, 2- and 3-hour fire designs are available for modular, panelized, and conventionally constructed buildings to meet virtually any application.

Watch these videos below to learn more about how to install Fiberock® Underlayment over STRUCTO-CRETE® Panels.

USG Fiberock® Underlayment over USG STRUCTO-CRETE® Brand Structural Panels:

USG Fiberock® Underlayment over sound mat on USG STRUCTO-CRETE® Brand Structural Panels: