Sign In

You're All Set

loginSuccess

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

forgotPassSuccess

Reset Password

You're All Set

resetPassSuccess

Change Password

You're All Set

changePassSuccess

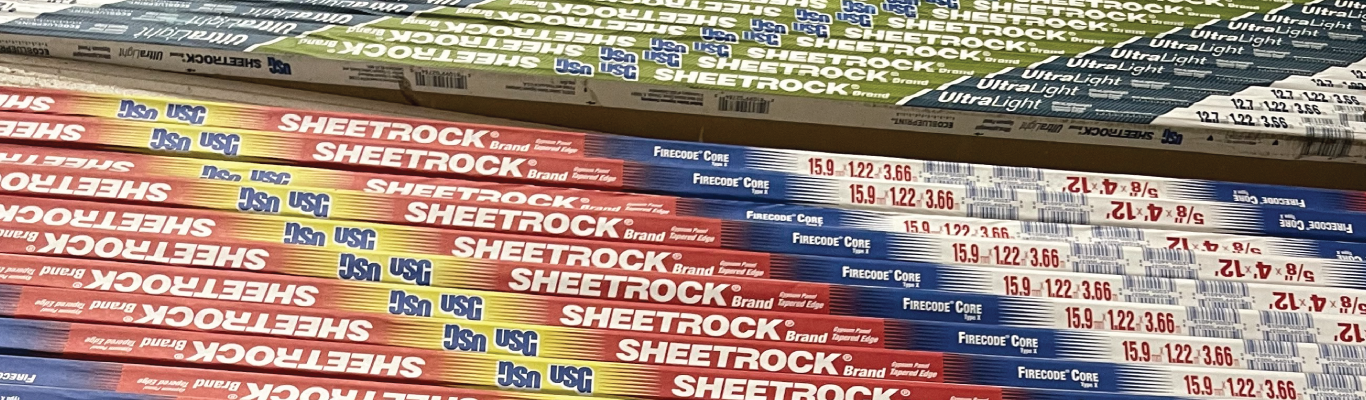

The Origins of USG Sheetrock® Brand

What is Drywall?

Prior to the invention of what we now know as drywall, plaster derived from the mineral gypsum was the only material used to create walls in most building construction. Unlike drywall, plaster is a wet material applied to wood lath that needs to dry completely before additional layers could be added. The industry really had no other options until Augustine Sackett, a manufacturer who created a laminated sheet of alternating layers of straw paper and tar used to make packing cases.

To Sackett, it seemed only natural that panels such as these could also form walls and ceilings. Not in their present highly flammable straw and tar combination, of course, but with the insertion of a fireproof ingredient. In 1888, he hit on the idea of substituting a thin layer of plaster of Paris for the hot tar, and obtained a patent on the concept in 1894, thus creating “Sackett Board.”

After a few formulations on the product and establishing plants for his Sackett Plaster Board Co., Augustine Sackett eventually partnered with United States Gypsum Company to help market his revolutionary product. By 1909, the trademark “Sackett” was hand-stamped on each panel as it was made; this is the origin of what we now know as drywall.

But USG was not done there, as advancements and innovations to Sackett Board continued in the years following; in 1910 a “folded edge” was designed to keep the board from crumbling and in 1913, the two interior plies of paper in the board were eliminated, leaving a solid gypsum core between the top and bottom sheets, and was rebranded as “Adamant Board.” Square edges were devised in 1916 and introduced to the industry the concept of two gypsum panels that could be joined flush along a wall for a (relatively) smooth surface that could be decorated without applying plaster, coining the term “wallboard.”

What is Sheetrock®?

By 1917, USG was marketing the early iteration of modern wallboard as “Adamant Panel Board,” which is quite a mouthful. When D.L. Hunter, a sales representative at the time for the company, felt that the product could use a brand refresh that more adequately represented the quality and performance of the product, his suggestion was to call it “Sheetrock;” the rest, they say, is history.

When USG introduced Sackett Board, it created what we now know as the drywall industry. When this gypsum board was rebranded to Sheetrock®, it began a legacy built upon quality, particularly its fireproof qualities and quick application, which made Sheetrock® Panels the specified choice for all government buildings in the wake of World War I.

Flash forward to the Chicago World’s Fair in 1933 and 1934, the largest construction project during the Great Depression, USG was tapped to supply Sheetrock® Panels that could stand two years of exposure on the outside of the semi-permanent structures devised for the event; 65% of the gypsum wallboard used in the fair’s exhibits was Sheetrock® Brand.

This project ended up becoming great exposure for USG, as Sheetrock® Brand began running advertisements across the nation’s leading magazines. Sheetrock® Brand’s reputation grew along with USG entering World War II when the company supplied mass quantities of building materials for War Department projects. Millions of square feet of Sheetrock® Brand wallboard lined the interiors of military base structures and plants erected for the manufacture of war materiel and contributed even more to the recognition of Sheetrock® Brand.

Establishing the Sheetrock® Brand

In the years following WWII, Sheetrock® Brand continued to gain public attention which coincided with gypsum wallboard gaining widespread acceptance in commercial construction. USG’s new metal C-stud and drywall screw afforded a fire-resistant system in high-rise construction and marked the final transition from plaster to drywall: both were introduced at the time of the largest building boom in history.

By the mid-1960s, markets began to change as large chain outlets for hardware supplies began to take hold with the capability to move large amounts of product. Soon, USG dedicated a national accounts department specifically to address the needs of these large nationwide or regional retailers, pushing Sheetrock® Brand to the forefront of consumers’ minds.

USG continued to establish the Sheetrock® Brand by taking part in a large-scale rehab project on apartment buildings across major cities in the United States in 1966. Instead of tearing down the structures and building anew, the facades were retained, and the interior apartments were updated with USG materials headlined by Sheetrock® Brand gypsum wallboard. The project was such a success and attracted a huge amount of publicity that Graham Morgan, then-CEO of USG, was appointed vice chairman of President Lyndon B. Johnson’s Committee on Urban Housing.

In Conclusion…

Jumping to the modern day, Sheetrock® Brand celebrated its 100th anniversary in 2017 and USG was the number 1 producer of gypsum wallboard in North America as well as the largest distributor of gypsum board achieved through decades of providing quality products. This legacy is what made Sheetrock® Brand one of the most widely recognized names in the drywall industry and cemented its place as a name synonymous with drywall.

With over a century of Sheetrock® Brand and counting, USG remains the #1 producer and distributor of gypsum wallboard in North America—learn more about our storied and enduring company history here.